Almost any material can be cut using a CNC machine. Popular materials are metals, plastics and wood.

In short, a drill bit moves up and down while an end mill moves left and right (note: some end mills can move in various directions).

End Mill

End mill cuts by rotating horizontally or laterally (side to side), while a drill bit cuts directly into the material by moving vertically downward.

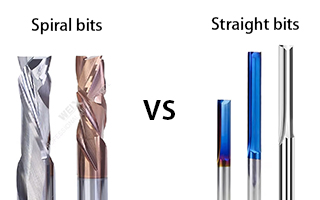

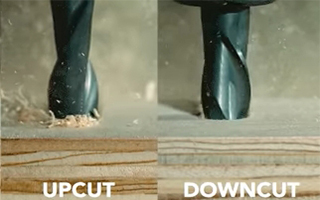

End mills come in various lengths, diameters, flutes, and types, which can be chosen based on the material being cut and the desired surface finish for the project.

End mills are the cutting tools of the milling world and are used for tasks such as slotting, profiling, contouring, counterboring, and chamfering.

End mills allow for cutting precise parts, ranging from machine components, jewelry designs, wood carvings, sign-making, plastic cutting, mold-making, to circuit boards.

Drill Bit

Drill bit cuts round holes straight down into the material by rotating them in a rotary drill.

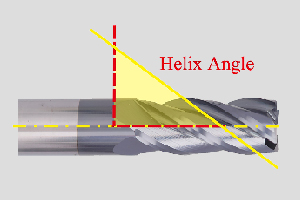

Most drill bits have flutes (grooves) that give them a twisted appearance and aid in cutting the material as the drill bit moves up and down within the hole.

HSS (High-Speed Steel) and carbide drill bits are fluted. (twist drill).

Exception to this rule is a diamond drill bit, which has a flat end instead of a pointed or grooved one.

If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, contact our order desk. We’d be happy to take your call and discuss specifics with you.

+86-0511-83373758|[email protected]

Leave A Comment

You must be logged in to post a comment.