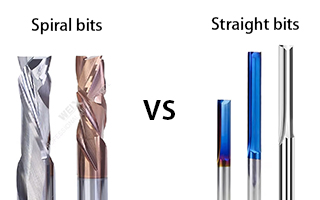

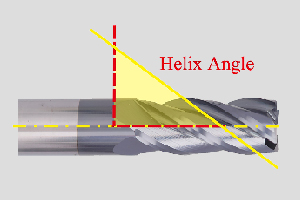

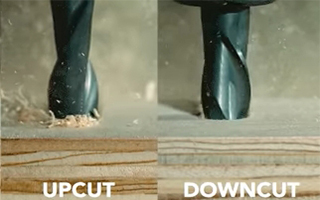

Spiral router bits are capable of creating extremely clean and smooth cuts. When using a spiral bit, there is less vibration during the cutting process and also less tear and wear on the router. Besides, spiral bits perform better than straight bits in plunging. However, when selecting spiral router bits, sizes are limited, and using a spiral bit is more dangerous.

Straight router bits are generally less expensive than spiral bits and have more size options. However, straight bits are not suitable for plunge cutting and are less durable than spiral bits. Due to their cutting angle, the rotation of a straight bit causes more vibration, leading to less precision.

Compared with traditional straight bits, spiral router bits have a longer service life, create much cleaner cuts, and are more efficient when it comes to cutting challenging workpieces like plywood, composites, or plastics. The higher prices of spiral bits may drive customers away, but in the long run, spiral bits are definitely cost-effective.

If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, contact our order desk. We’d be happy to take your call and discuss specifics with you.

+86-0511-83373758|[email protected]

Leave A Comment

You must be logged in to post a comment.