When it comes to aluminum machining, the right helix angle can be the key to unlocking success. Understanding and harnessing the concept of helix angles can greatly optimize your machining process, ultimately leading to superior results.

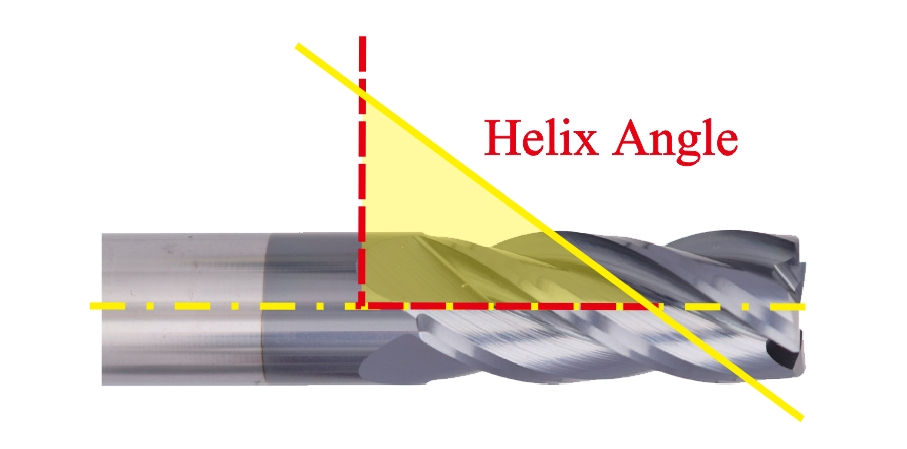

Understanding Helix Angles:

The helix angle of an end mill pertains to the angle formed between the tool’s centerline and the edge of its rake face. The helix angle is a core geometric parameter of machining cutters. It is important as it affects the material removal rate, feed rate, surface finish, cutting force distribution, tool strength, and tool life. In the realm of aluminum machining, the choice of the appropriate helix angle can significantly impact your machining outcome, differentiating between satisfactory and exceptional results.

Assessing Application Needs:

The selection of the helix angle hinges on the goals of your machining project. For roughing applications, a deliberate choice of a slower 35° helix angle is advised. Its elevated strength and capacity to handle larger chip loads make it ideal for tackling rough surfaces. On the flip side, the higher 45° helix angle suits finishing applications remarkably well. It excels when the tool operates at higher speeds while delicately removing minimal material, resulting in smoother and finer surfaces.

Meanwhile, the medium 40° helix angle strikes a balance between the advantages of both slow and high helix angles. It functions effectively in both roughing and finishing applications, offering versatility to suit a variety of machining needs.

A Range of Choices:

At WEIX, we offer a wide array of high-performance aluminum end mills featuring three distinct helix angle configurations: 35°, 40°, and 45°.

● 3 Flute, 35° Helix

● 3 Flute, 40° Helix

● 2 Flute, 45° Helix

● 3 Flute, 45° Helix

● 3 Flute, 45° Helix with Chipbreaker

Link to Product

Conclusion:

In the realm of aluminum machining, the choice of helix angle holds the power to transform your results. WEIX ensures ample options for helix angles to cater to varied applications. With a profound understanding of different helix angles’ characteristics, you’re poised to explore and elevate your aluminum machining endeavors. Experience improved efficiency, quality, and machining prowess by harnessing the potential of helix angles.

WEIX Tool Manufacturing is an industry-leading provider of CNC machining services. Feel free to contact us for your rapid manufacturing needs.

Leave A Comment

You must be logged in to post a comment.