A question we often get asked here at WEIX regarding spiral flute cutters is whether to use an up cut or down cut router bit. And the answer is that it all depends on your machine, materials and your desired finish. When it comes to picking the most suitable bit — it will be determined by your job’s particular demands.

The Differences Between Up Cut and Down Cut

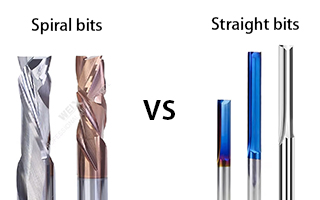

Spiral flute routers are available in both up cut and down cut in a wide range of diameters which means that you have plenty of choices when it comes to selecting the right tool.

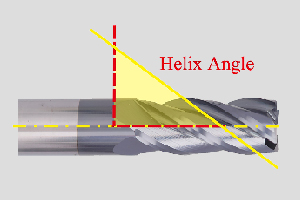

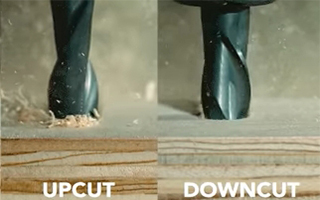

Up cut spirals work similarly to a HSS twist drill. Under right hand rotation, the spiral pulls upwards — bringing the swarf up and out of the workpiece. This can be a huge advantage for mortising as it can remove swarf from a narrow, deep mortice.

Importantly, it also exerts an upward force on the workpiece. An up cut spiral might not work as well for edge finish on the top surface because the upward cutting action can lift the timber edge and result in splintering but it will reduce splintering on the bottom edge. Set your cutter height so the bit protrudes through the bottom of the timber and you will have an up cut spiral action pulling up into the bottom edge. This will produce a chip free, clean finish on the bottom edge.

A potential disadvantage of up cuts is that when cutting thin, light materials such as Acrylic sheets the up cut may lift the workpiece and distort the cut or cause vibration.

The opposite is true of down cut, While they still operate in a right hand rotation, the spiral runs downward applying a down shear pressure to the workpiece’s top edge. This will stabilise the cutting process on the top edge but might leave the bottom edge prone to breakout. Down cut spirals are not generally recommended for mortising as the swarf will be directed down into the bottom of the slot making it difficult to clear sawdust from the cutting operation. Finishing passes with a down cut can be effective in this case as less swarf is generated when performing finishing passes and top edge tear out is eliminated by the downward force applied.

The downward cutting action will tend to push thin, light materials down against the bench reducing vibration during machining.

The benefits and disadvantages of up cut/down cut spirals are reversed if your machine is bench mounted or set up in a router table in an inverted position.

WEIX has rich experience in supplying industrial-quality router bits for furniture factories, woodworking tool distributors, and manufacturing and metalworking industries companies across the world. If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, please feel free to contact us. We’d be happy to take your call and discuss specifics with you.

+86-0511-83373758|[email protected]

Leave A Comment

You must be logged in to post a comment.