Choosing between two flutes vs. three flutes end mills when machining in aluminum depends on several factors, including the specific operation being performed, the desired surface finish, and the machine’s capabilities. The depth of cut and radial engagement will also affect the flute count, in terms of tool pressure from increased points of contact along the cutting edge.

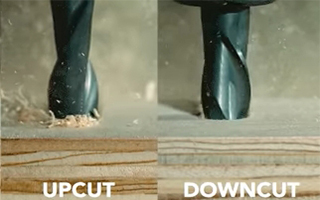

Two flutes end mill features two cutting edges (flutes) and provides ample space for chip evacuation. The larger flute space allows for increased radial engagement and chip loads making it well-suited for aggressive material removal.

When to Use two flutes end mill ?

High Material Removal Rates: When your priority is to remove large volumes of aluminum quickly, two flutes end mill is your ideal choice. The increased chip space and aggressive cutting action facilitate rapid stock removal, increasing the tools’ ability to clear chips effectively.

Low-Power Machines: If you’re using a low-power milling machine or a machine fixturing with limited rigidity, two flutes end mill can be beneficial because its design puts less strain on the machine.

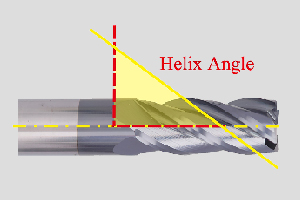

Deep Depth of Cuts or Long Sidewall Consideration: Fewer points of contact will provide less radial push-off and reduce wall taper significantly when paired with optimized helix angles.

Three flute end mill comes with three cutting edges (flutes), making it more versatile in certain scenarios. The additional flute provides an easier transition from flute to flute, changing the characteristics of the surface finish.

When to Use three flutes end mill ?

Finishing Operations: For achieving exceptional surface finishes, three flutes end mill is more suitable due to reduced radial forces. The lower radial forces minimize the risk of part deformation and ensure higher machining accuracy.

Chip Evacuation is a Concern: Three flute end mills offer an excellent balance between chip removal and surface finish. It is especially useful in scenarios where chip evacuation might be a concern, but smooth surface finishes are still essential.

Roughing: Three flutes end mills provides increased stability and reduces the radial forces acting on the tool, resulting in better surface finishes and improved tool life. However, they remove material more slowly than two flutes end mills, but the balance between lighter feed rate with the additional flute will often benefit the user.

In conclusion, the choice between two flutes and three flutes end mill when machining in aluminum depends on the specific requirements of your project. Ultimately, the best way to choose the right end mill when machining in aluminum is to work directly with our Sales or Engineering teams. They will help you assess your specific needs and recommend the right tool for your application.

WEIX has rich experience in supplying industrial-quality router bits for furniture factories, woodworking tool distributors, and manufacturing and metalworking industries companies across the world. If you’re looking to purchase quality end mills at affordable prices, or have questions about where to begin, please feel free to contact us. We’d be happy to take your call and discuss specifics with you.

+86-0511-83373758|[email protected]

Leave A Comment

You must be logged in to post a comment.